Screw, cylinder, snail and barrel refurbishment

Anything can be refurbished

A new screw, cylinder, worm, snail and barrel is very expensive, and whether it is a matter of mixing and conveying plastics, rubber, liquids or other products under high pressure and heat, optimal functionality is crucial to the operations - this goes for both volume and quality of the finished product. Through 30 years K.A.L. has developed an unique expertise within screw refurbishment, snail refurbishment, worm refurbishment and barrel refurbishment, and other vital, round process parts. Our results and experience show that parts refurbished by K.A.L. fully matches the standards of new ones as far as functionality and life is concerned.

Our service concept is based on 4 elements:

- Measurement and evaluation is performed directly at customer site

- Feedback within 24 hours after receipt of the equipment

- A maximum delivery time of 2 weeks

- All refurbishment prices are fixed

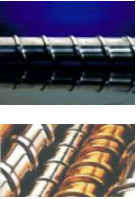

Screws and worms specifics

Screw refurbishment: Worn-out, broken and crooked screws and worms and be refurbished and the geometry can be changed. The plasma-welding medium is matched the type of metal of the barrel in which the screw or the worm is operating. Also very damaged threads and bottoms can be refurbished, and extensions are possible too.

Barrels specifics

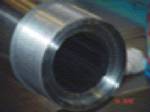

Barrel refurbishment: The barrel can be refurbished no matter whether it has been subject to gas-nitriding or if it is made of bi-metal, also if the barrel is very worn out in a limited area.

- Honing to a "clean measurement" and if necessary reestablishment of the hardness

- Insertion of a new piece int he barrel - click here to see examples

Other forms of refurbishment

Thanks to our know-how and production equipment, we are able to offer many different forms than screw refurbishment, cylinder refurbishment, snail refurbishment and barrel refurbishment - and we certainly do that.

Examples:

- A broken column is assembled by means of a screw bushing, welded and grinded

- A worn out and/or damaged shaft is cleaned by grindind. Followed by hard-chromium plating and then circular grinding to the required finished dimensions

- Suspension joints for injection moulding machines are provided with new bronze bushings and shafts reconditioned with hard-chromium

- Surfaces to resist wear are welded to various workpieces followed by subsequent grinding

- Refurbishment of pumps and valve casings

- Refurbishment of different kinds of decants

Feed boxes, blocking sets, rolls and nozzles are refurbished with equal high quality results.

There are many possibilities - please contact us, and we will find a solution, which is both cheaper and faster compared to new manufacture.

For further information on technology, materials and coatings etc, please click here >> Technical data

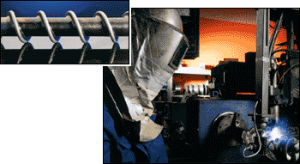

The screw is cleaned and welded on the threads..

The welding is effected on a costumised plasma weldingrobot. Different welding media may be used, e.g cobalt- or nickel-alloy powder.

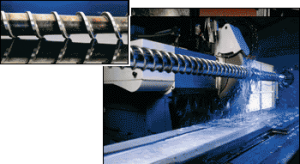

The welded screw is ground to size using cylindrical grinding.

The cylindrical grinding is effected in a CNC controlled cylindrical grinding machine.

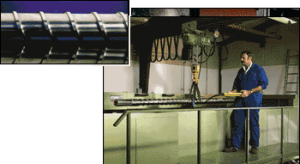

The fast process is polishing the screw.

The polishing is effected using a fully automatic vibration-polishing machine.

Product range - new manufacture

Product range - new manufacture

Screws - screw elements, worms and worm heads

Design, measurements, through hardening, gas nitriding, Stellite 12, Colmonoy 56, Wolfram Carbid, barrier threads, mixers, decontamination, PVD coating

Barrels and feeding boxes

Barrels and feeding boxes

Measurements, (cylinder) honing, insertion of new pieces, through hardening,

gas nitrided, bimetal, bimetal with Wolfram Carbid, decontamination, feeding holes, keys in feeding zone

Blocking sets

Weld-up of sealing areas, gas nitrided, through hardened, Wolfram Carbid.

Rolls

Rolls

Back-up rolls, pipe rolls, clip rolls, cooling rolls,

pinion wheels, stark rolls, stamp rolls, contact rolls, chromium coating, PVD coating.

Nozzles

Gas nitrided, through hardened, chromium coating, PVD coating

Recent Comments